Keeping track of your stock is an integral part of running your hospitality venue. While other costs rise, knowing exactly which items are bringing you profit and where you might be losing out is more important than ever.

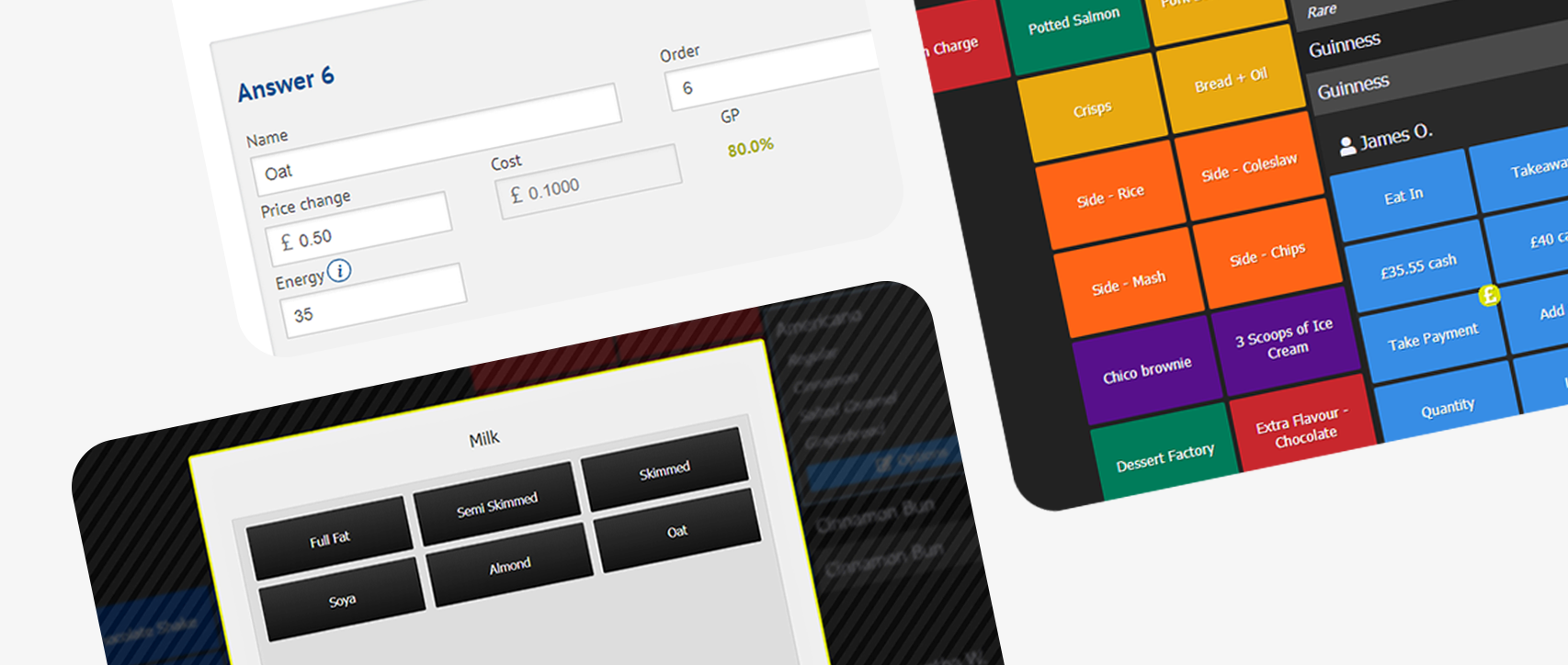

Recording your stock invoices and comparing with your revenue is simply not enough anymore, and there are various systems that can help you to delve deeper into your actual costs. The Kobas stock system allows you to record and manage every item in your inventory to see exactly what makes up your overall GP and variance figures.

What are the benefits of using a Stock Management System?

An in-depth stock management system allows you a far deeper understanding of what goes on in your kitchen and behind your bar, and allows for more informed decisions across the rest of your business.

Anyone can take a menu item and calculate the GP it should be making you each time you sell it, but without a well-maintained and consistent stock system in place, you will never know if you are really achieving that. Some cheaper items that you think are money-makers will be over-ordered, resulting in wastage, while some that on the surface look more costly, may be bringing you a better profit overall.

Major benefits include:

Informed menu decisions

That top-selling item that’s bringing big sales? Make sure that the ingredients used are actually bringing in the profit you think. On the other hand, you might have a high-profit menu item that isn’t selling very well. Use that insight to tweak the item – maybe adjust how it’s marketed or what it’s served with.

Better supplier management

Use your thorough understanding of each item’s value to research or negotiate supplier’s prices, or to better manage your delivery schedules to reduce waste.

Enhanced staff training

You’ll soon tell where your operational issues lie – use this information to solve portioning or inventory control issues and to ensure consistency, especially across multiple sites.

Streamlined operations and efficiency

Save time and improve accuracy by ditching the pen and paper when completing stock checks. Better yet, a stock management system keeps your data centralised and consistent – crucial for multi-site operations.

Improve stock order accuracy

Use sales and stock insights to your advantage by analysing sales trends to get your stock orders right, reducing wastage often experienced from under and over stocking.

How often should I count my stock?

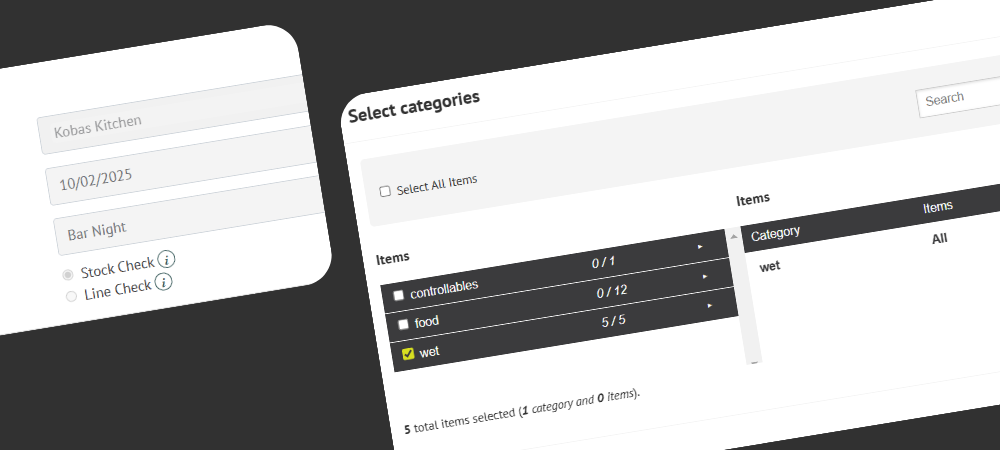

The Kobas stock system doesn’t require you to count stock on any particular schedule, so you can decide this for yourself. Factors such as your revenue, the complexity of your menu (and therefore the amount of different items you hold), and the shelf-life of your items are all important to take into account.

You may wish to count different items on different schedules, such as your fresh items once a week and dry store items once a month, or your food and wet items on different days. These are all fine methods, you just need to make sure you run your reporting between the correct dates when analysing your results to ensure you have complete visibility across all items.

Onto the tips and tricks

As with all systems, the information you get out is only as good as the information you put in. Here are some tips on using the Kobas stock system to your best advantage to increase the benefits you see, and to make your life easier too!

🔢 1. Start before you count

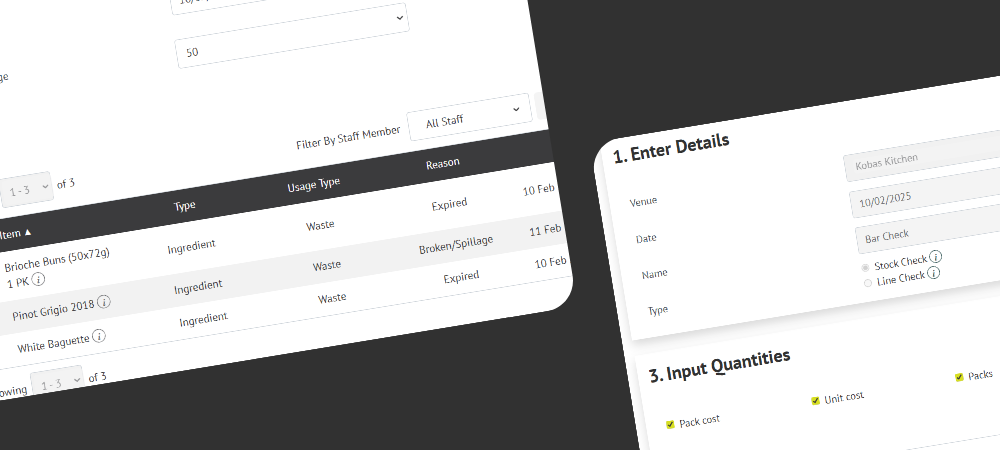

For the most accurate stock count results, make sure all orders and deliveries for the period are recorded before you begin. And, log all wastage to the system to reflect true stock levels. You can record waste during each shift on the Kobas EPoS or Kitchen Display System with a dedicated reason, and you can add it retrospectively if you need to as well within Kobas Cloud.

Even after completing your stock count, you can still adjust your deliveries or wastage if needed. However, encouraging your staff to do this as part of their daily processes and ensuring they are invested in the management of costs, is the more efficient route. Better yet, it helps instil a culture of accountability and accuracy around stock control. When your staff are engaged, your venue benefits from more reliable data, reduced discrepancies, and improved profitability.

✅ 2. Estimates and counting processes

The key when it comes to actual counts is consistency. Many people have their own methods for counting, all of which are valid, but once you have decided on one, try to stick to it for every item and every count.

If you can, ensure the same person counts each time, and train other staff in the same way. If you have multiple sites, adopt the same approach everywhere so you can easily check the counts of any venue, and staff can easily transfer between venues without additional training.

If you use estimate counting, for example counting in decimals for bottles or lifting kegs to measure their weight, having the same person count each time is vital. Even if that member of staff is always generous, the same over-estimate will be built in each week and not result in a variance.

🕘 3. Same time, same place

Consistency is key (are you sensing a theme here?). Whether you count weekly, monthly or ad hoc, try to count at the same time in the sales and order cycle. If you are primarily a weekend venue, count consistently before or after the weekend, and before or after your largest deliveries are received.

This means each time you do a stock count, the volume of each item in stock should be fairly similar and any miscounts or anomalies can be easily spotted.

Suddenly have 200 bottles of your most expensive Champagne and only 6 of the bestselling Prosecco? Maybe someone’s received a delivery onto the wrong shelf or entered the count on the wrong line. Whatever the issue may be, the easier it is to spot… the easier it is to fix.

This means each time you do a stock count, the volume of each item in stock should be fairly similar and any miscounts or anomalies can be easily spotted.

🍔 4. Know your venue, your items, and your stock system

It’s a good idea to get to know your stock system well and to use its features to suit your specific venue. If you have multiple stock areas or more than one kitchen or bar, then find a way to make the system work for you.

Kobas allows you to create multiple stock checks, view the results for them all simultaneously and then merge once complete. This approach means you can count the store room, main bar and dining room separately and check each area for miscounts, but only need to refer to one stock check when coming back to it another time.

You should also look at how each item is counted, how it’s ordered and how it’s stored, and avoid having to do any mental arithmetic wherever possible!

In Kobas, you can count in packs, units or in loose measurements such as grams or mls, or a combination of them all. That means you can count three boxes of wine and two and a half bottles on the bar without having to know your six times table, and there’s no need to count beers in 24s either – life’s too short!

🧂 5. Consider the “awkward” items

Some items are notoriously difficult to keep track of and need to be treated differently or with a special process in mind. Examples of these include high-volume, low-value items such as teabags or sugar sachets, items where recipe usage is very small, such as cocktail bitters, or items that are packaged and processed such as post-mix syrups.

There are a number of ways to deal with these:

Track actual usage only

By simply recording deliveries and counting the stock you have on hand, you’ll be able to see the amount of these items lost each week, and therefore a cost. As this will show as a variance, you can then record this usage amount as waste. This method will reduce your variance percentage but won’t improve your GP.

If you track wastage throughout the stock period then this creates some theoretical usage, and any variance you see can be attributed to sales. This will give you a better understanding of your actual costs and GP for these items but leave you with a higher variance percentage.

Count in estimates

When items are very high volume, then counting just full packs can be useful. This will give an idea of the usage but also saves time and leaves room for other uses of these items. This method works well for items such as teabags that may be used by staff as well as sold.

Do your calculations

If you really want to control the items along with the rest of your ingredients, it’s important to make sure that your recipes are accurate and that you have processes in place.

A good example of this is post-mix syrups – to include the precise amount of syrup used in each drink requires knowledge of your drink dispenser system and how it’s been installed. You can include a very small amount in each recipe, or create a batch recipe for each pack eg. 7ltrs syrup = 45ltrs Batch Soft Drink. As with all recipes, it’s worth checking the accuracy of these over time.

For any items being used across many areas of the business, for example milk, make sure that staff across all teams in your venue are aware of stock processes and are following them in the same way.

Leave them out

Sometimes, it’s just not worth the hassle! There may be some items that you simply decide not to include in your stock system and GP calculations. If you do decide to take this route, make sure they are fully removed and don’t appear anywhere in your system, in counts, deliveries or recipes. Otherwise, you may see a variance if they are included by mistake in any one.

With a system like Kobas, not only do you gain deeper insight into your stock, but also give your team the tools to make more informed decisions. From optimising menu pricing and negotiating better supplier deals, to improving stock ordering accuracy and operational efficiency, the benefits are clear.

And the key ingredients? Consistency, accuracy, and getting your staff on board. When these habits become part of your venue’s everyday routine, stock control goes from another task to a key driver in your business’s success.

Want to see the Kobas system in action?

Kobas enables teams across the hospitality industry to manage all areas of the business, from one connected and complete system.